- 変位センサ

- 渦電流センサ

- コンフィギュレータ

- eddyNCDT 3001

![eddyNCDT 3001 渦電流センサ]() エレクトロニクス内蔵のコンパクトな渦電流センサ

エレクトロニクス内蔵のコンパクトな渦電流センサ - eddyNCDT 3005

![eddyNCDT 3005 渦電流センサ]() 機械やシステムに組み込むための小型化センサシステム

機械やシステムに組み込むための小型化センサシステム - eddyNCDT 3060/3070

![eddyNCDT 3060/3070 渦電流センサ]() 産業用アプリケーション向け高性能センサシステム

産業用アプリケーション向け高性能センサシステム - eddyNCDT 3300

![eddyNCDT 3300 渦電流センサ]() 高速測定に最適

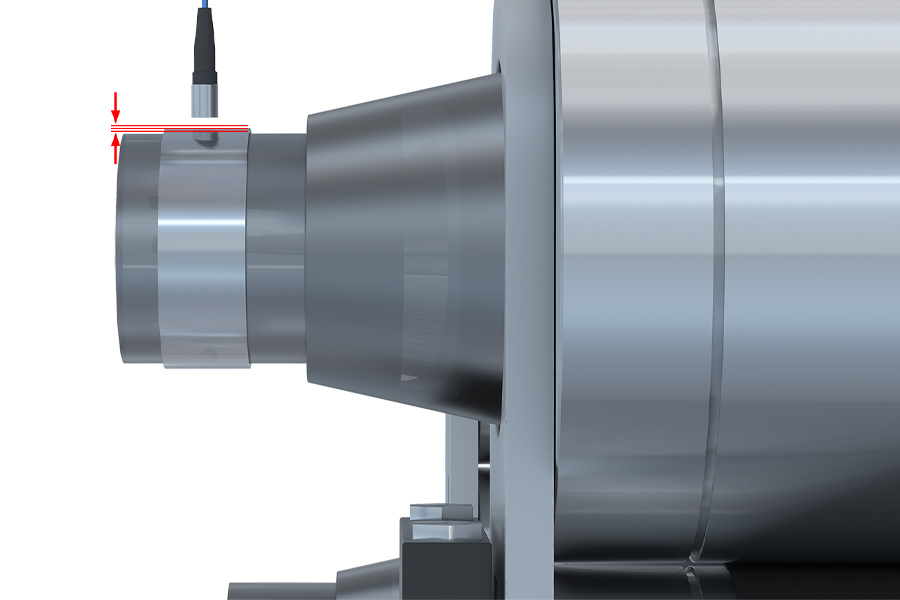

高速測定に最適 - SGS 4701スピンドルの膨張測定

![SGS 4701スピンドルの膨張測定 渦電流センサ]()

- お客様ごとのカスタマイズセンサ

![お客様ごとのカスタマイズセンサ 渦電流センサ]()

- 静電容量センサ

- コンフィギュレータ

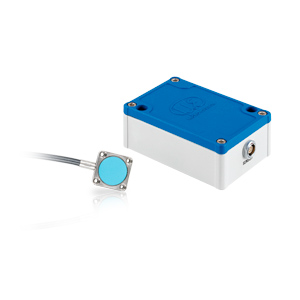

- capaNCDT 6110

![capaNCDT 6110 静電容量センサ]() 産業アプリケーションでの使用に理想的

産業アプリケーションでの使用に理想的 - capaNCDT 61x0/IP

![capaNCDT 61x0/IP 静電容量センサ]() 産業用アプリケーションのための堅牢な設計

産業用アプリケーションのための堅牢な設計 - capaNCDT 61x4

![capaNCDT 61x4 静電容量センサ]() 長尺ケーブル用アクティブ測定システム

長尺ケーブル用アクティブ測定システム - capaNCDT 6200

![capaNCDT 6200 静電容量センサ]() 高精度マルチチャネル測定に最適

高精度マルチチャネル測定に最適 - capaNCDT 6228

![capaNCDT 6228 静電容量センサ]() 高温アプリケーションに最適

高温アプリケーションに最適 - capaNCDT 6500

![capaNCDT 6500 静電容量センサ]() 高精度マルチチャネル測定に最適

高精度マルチチャネル測定に最適 - capaNCDTセンサ

![capaNCDTセンサ 静電容量センサ]()

- お客様ごとのカスタマイズセンサ

![お客様ごとのカスタマイズセンサ 静電容量センサ]()

- combiSENSOR

![combiSENSOR 静電容量センサ]()

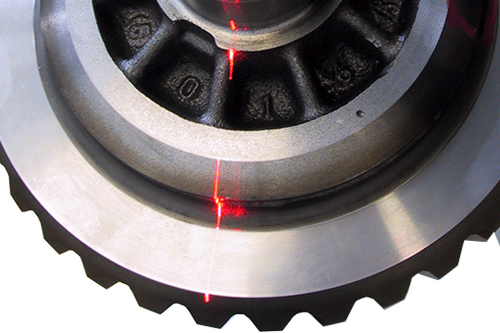

- capaNCDT DTV

![capaNCDT DTV 静電容量センサ]()

- capaNCDT MD6-22

![capaNCDT MD6-22 静電容量センサ]()

- capaNCDT TFG6220

![capaNCDT TFG6220 静電容量センサ]() 導電性フィルムの厚さ測定

導電性フィルムの厚さ測定

- レーザセンサ

- コンフィギュレータ

- optoNCDT 1220

![optoNCDT 1220 レーザセンサ]() OEMおよびシリーズ用途に最適化

OEMおよびシリーズ用途に最適化 - optoNCDT 1320

![optoNCDT 1320 レーザセンサ]() 正確な測定のためのコンパクト設計

正確な測定のためのコンパクト設計 - optoNCDT 1420

![optoNCDT 1420 レーザセンサ]() 高精度測定のためのスマートなレーザーセンサ

高精度測定のためのスマートなレーザーセンサ - optoNCDT 1900

![optoNCDT 1900 レーザセンサ]() アドバンストオートメーション向けの革新的なレーザー変位センサ

アドバンストオートメーション向けの革新的なレーザー変位センサ - optoNCDT 2300

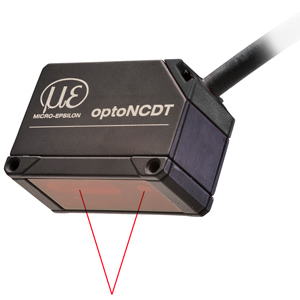

![optoNCDT 2300 レーザセンサ]() 精密測定のための高動的レーザーセンサ

精密測定のための高動的レーザーセンサ - optoNCDT 5500

![optoNCDT 5500 レーザセンサ]() ハイエンドアプリケーション用高動的レーザーセンサー

ハイエンドアプリケーション用高動的レーザーセンサー - 青色レーザー(BL)センサ

![青色レーザー(BL)センサ レーザセンサ]() 金属および有機物質用の青色レーザーセンサ

金属および有機物質用の青色レーザーセンサ - レーザーライン(LL)センサ

![レーザーライン(LL)センサ レーザセンサ]() 光沢のある金属や構造物の表面に最適

光沢のある金属や構造物の表面に最適 - 長距離レーザーセンサ

![長距離レーザーセンサ レーザセンサ]() 大きな測定距離に最適

大きな測定距離に最適 - お客様ごとのカスタマイズセンサ

![お客様ごとのカスタマイズセンサ レーザセンサ]()

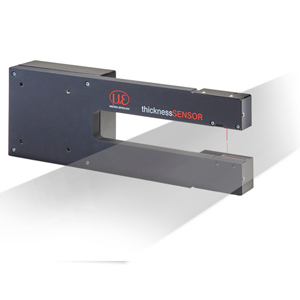

- thicknessSENSOR

![thicknessSENSOR レーザセンサ]()

- 共焦点式センサ

- コンフィギュレータ

- 共焦点クロマティックセンサ

![共焦点クロマティックセンサ 共焦点式センサ]()

- confocalDT IFD2411

![confocalDT IFD2411 共焦点式センサ]() シリーズアプリケーション用コンパクトコントローラ

シリーズアプリケーション用コンパクトコントローラ - confocalDT IFD2410/2415

![confocalDT IFD2410/2415 共焦点式センサ]() コントローラ内蔵の小型センサ

コントローラ内蔵の小型センサ - confocalDT IFC2421/22

![confocalDT IFC2421/22 共焦点式センサ]() 産業アプリケーション用シングル/デュアルチャネルコントローラ

産業アプリケーション用シングル/デュアルチャネルコントローラ - confocalDT IFC2465/66

![confocalDT IFC2465/66 共焦点式センサ]() 高速かつ高精度な測定用シングル/デュアルチャネルコントローラ

高速かつ高精度な測定用シングル/デュアルチャネルコントローラ - 付属品

- 干渉計(白色光)

- interferoMETER 5200-TH

![interferoMETER 5200-TH 干渉計(白色光)]() 薄い層の安定したインライン測定

薄い層の安定したインライン測定 - interferoMETER 5400-DS

![interferoMETER 5400-DS 干渉計(白色光)]() ナノメートル精度の絶対距離測定

ナノメートル精度の絶対距離測定 - interferoMETER 5400-TH

![interferoMETER 5400-TH 干渉計(白色光)]() サブマイクロメートル精度の安定した厚さ測定

サブマイクロメートル精度の安定した厚さ測定 - interferoMETER 5600-DS

![interferoMETER 5600-DS 干渉計(白色光)]() サブナノメートル精度の絶対距離測定

サブナノメートル精度の絶対距離測定 - interferoMETER 5420-TH

![interferoMETER 5420-TH 干渉計(白色光)]() シリコンウェーハの高精度厚さ測定

シリコンウェーハの高精度厚さ測定

- interferoMETER 5200-TH

- レーザー距離センサ

- optoNCDT ILR1171

![optoNCDT ILR1171 レーザー距離センサ]() 屋外でも使用可能な高速センサ

屋外でも使用可能な高速センサ - optoNCDT ILR2250

![optoNCDT ILR2250 レーザー距離センサ]() 高性能レーザー距離センサ

高性能レーザー距離センサ - optoNCDT ILR3800

![optoNCDT ILR3800 レーザー距離センサ]() 産業用高性能レーザー距離センサー

産業用高性能レーザー距離センサー - optoNCDT ILR104x

![optoNCDT ILR104x レーザー距離センサ]() コンパクトで信頼性の高いレーザー距離センサ

コンパクトで信頼性の高いレーザー距離センサ

- optoNCDT ILR1171

- インダクティブセンサ(LVDT)

- induSENSOR DTD プローブ

![induSENSOR DTD プローブ インダクティブセンサ(LVDT)]() コンパクトなケーブルコントローラ付きプローブ

コンパクトなケーブルコントローラ付きプローブ - induSENSOR DTAゲージヘッド

![induSENSOR DTAゲージヘッド インダクティブセンサ(LVDT)]() LVDT 測定プローブ

LVDT 測定プローブ - induSENSOR DTAセンサ

![induSENSOR DTAセンサ インダクティブセンサ(LVDT)]() LVDT 変位センサ

LVDT 変位センサ - induSENSOR LDR

![induSENSOR LDR インダクティブセンサ(LVDT)]() リニア変位センサ

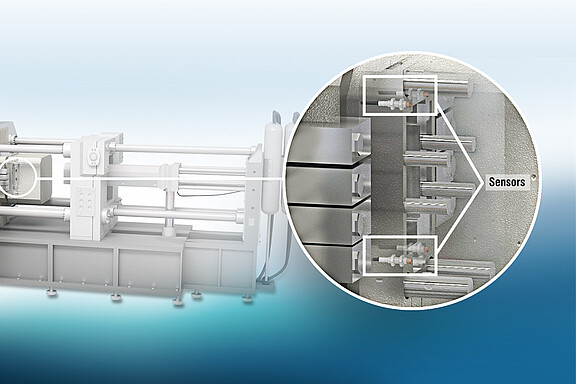

リニア変位センサ - クランピングストロークセンサ

![クランピングストロークセンサ インダクティブセンサ(LVDT)]() クランピング位置監視用センサ

クランピング位置監視用センサ - MSC7x0xコントローラ

![MSC7x0xコントローラ インダクティブセンサ(LVDT)]()

- induSENSOR EDS

![induSENSOR EDS インダクティブセンサ(LVDT)]() エレクトロニクス内蔵のロングストロークセンサ

エレクトロニクス内蔵のロングストロークセンサ - お客様ごとのカスタマイズセンサ

![お客様ごとのカスタマイズセンサ インダクティブセンサ(LVDT)]()

- induSENSOR DTD プローブ

- 磁気誘導センサ

- mainSENSOR MDS-35/-45

![mainSENSOR MDS-35/-45 磁気誘導センサ]() M12、M18、M30設計の堅牢なセンサ

M12、M18、M30設計の堅牢なセンサ - mainSENSOR MDS-40-MK

![mainSENSOR MDS-40-MK 磁気誘導センサ]() シリーズアプリケーション用センサ

シリーズアプリケーション用センサ - mainSENSOR MDS-40-LP

![mainSENSOR MDS-40-LP 磁気誘導センサ]() 回路基板仕様のセンサ

回路基板仕様のセンサ - お客様ごとのカスタマイズセンサ

![お客様ごとのカスタマイズセンサ 磁気誘導センサ]()

- mainSENSOR MDS-35/-45

- ワイヤセンサ

- 統合とOEM向けワイヤセンサ

![統合とOEM向けワイヤセンサ ワイヤセンサ]() プラスチック製ハウジングの小型センサ

プラスチック製ハウジングの小型センサ - 工業用途向けワイヤセンサ

![工業用途向けワイヤセンサ ワイヤセンサ]() アルミニウム製ハウジングの堅牢なセンサ

アルミニウム製ハウジングの堅牢なセンサ - 高速での測定用ワイヤセンサ

![高速での測定用ワイヤセンサ ワイヤセンサ]() 高いワイヤ加速度用

高いワイヤ加速度用 - メカニクス

![メカニクス ワイヤセンサ]() エンコーダ取り付け用ワイヤメカニクス

エンコーダ取り付け用ワイヤメカニクス

- 統合とOEM向けワイヤセンサ

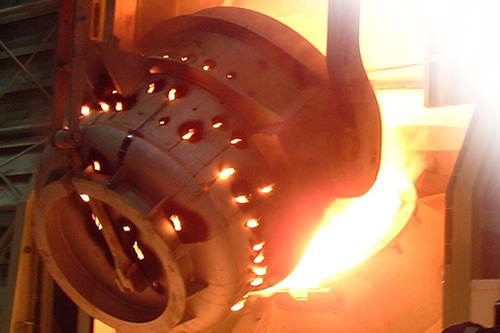

- 渦電流センサ

- 産業用センサ

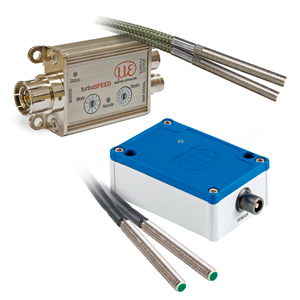

- 回転数センサ

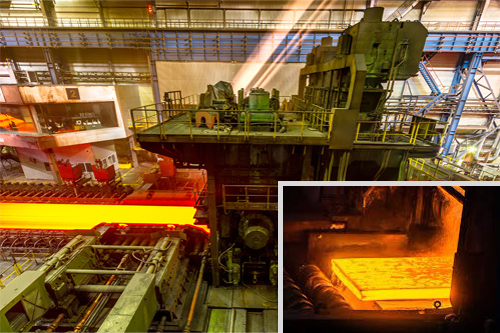

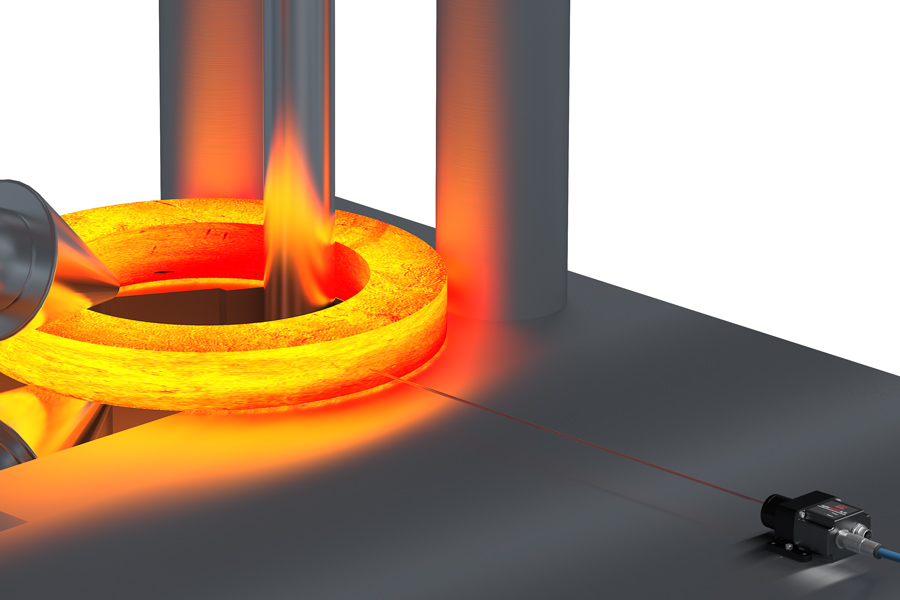

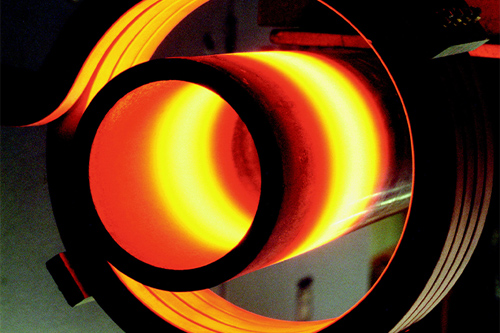

- 赤外線パイロメータ

- thermoMETER UC

![thermoMETER UC 赤外線パイロメータ]() 高性能な産業用パイロメータ

高性能な産業用パイロメータ - thermoMETER SE

![thermoMETER SE 赤外線パイロメータ]() 堅牢な超小型パイロメータ

堅牢な超小型パイロメータ - thermoMETER FI

![thermoMETER FI 赤外線パイロメータ]() 完全に統合されたコンパクトなパイロメータ

完全に統合されたコンパクトなパイロメータ - 特殊な用途に対応したパイロメータ

![特殊な用途に対応したパイロメータ 赤外線パイロメータ]()

- thermoMETER UC

- 熱探知カメラ

- 波面計測/光学部品計測

- カラー測定システム・カラーセンサ・LEDアナライザー

- 光ファイバーセンサ

- インターフェース・算出処理ユニット

- 2D/3D 計測技術

- 3Dセンサ

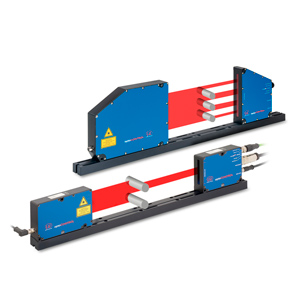

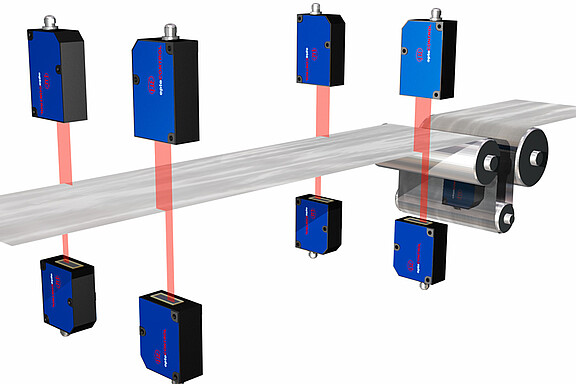

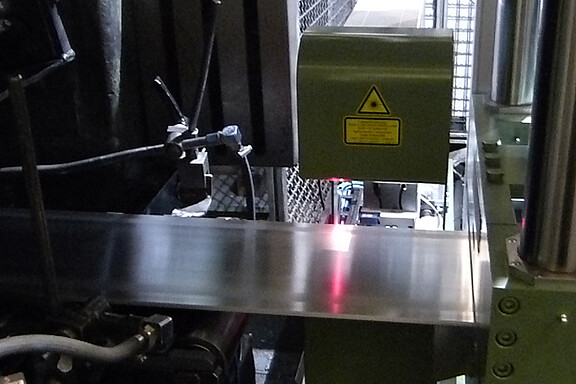

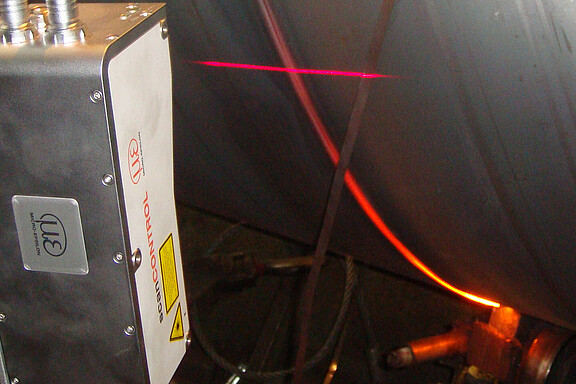

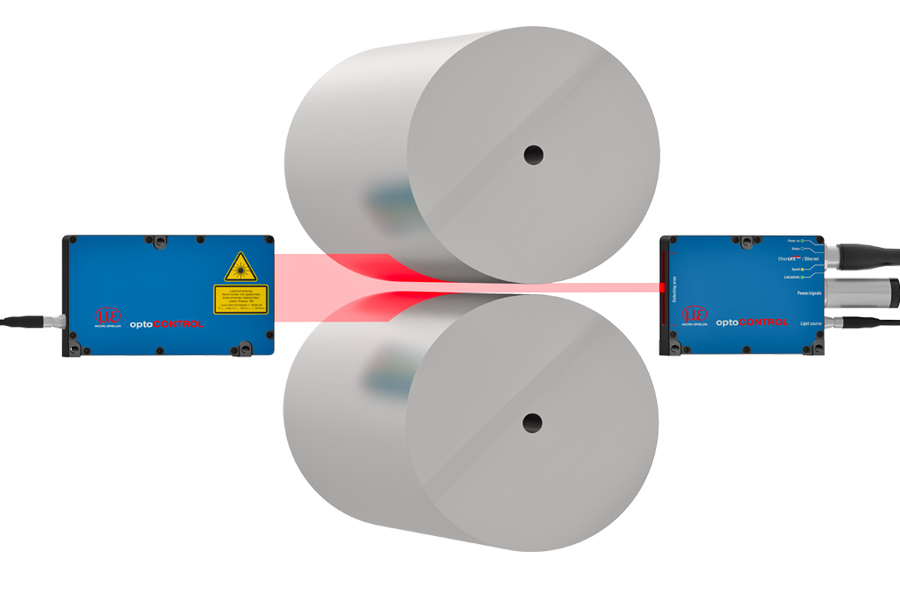

- 光学式精密マイクロメータ

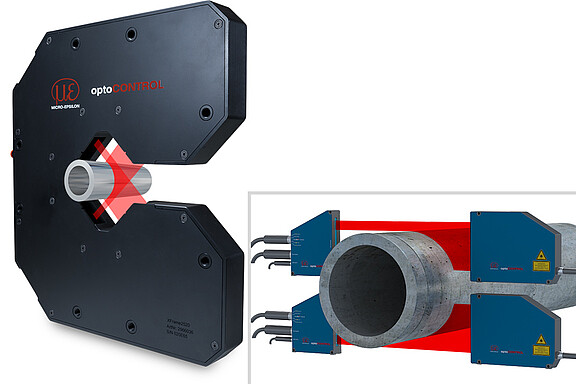

- optoCONTROL 1200

![optoCONTROL 1200 光学式精密マイクロメータ]() 小型高速マイクロメータ

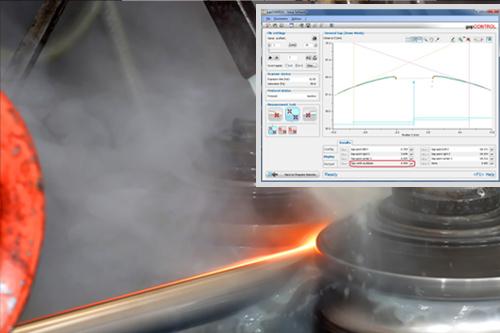

小型高速マイクロメータ - optoCONTROL 2520

![optoCONTROL 2520 光学式精密マイクロメータ]() 小型レーザーマイクロメータ(クラス1M)

小型レーザーマイクロメータ(クラス1M) - optoCONTROL 2700

![optoCONTROL 2700 光学式精密マイクロメータ]() 高い要求に応える高性能マイクロメータ

高い要求に応える高性能マイクロメータ

- optoCONTROL 1200

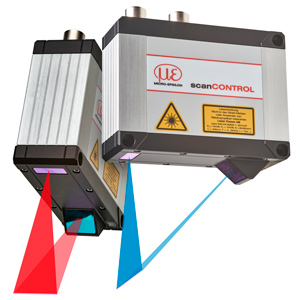

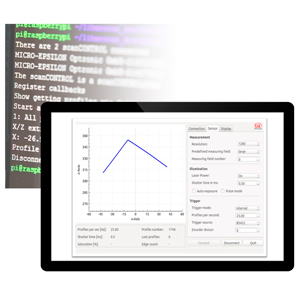

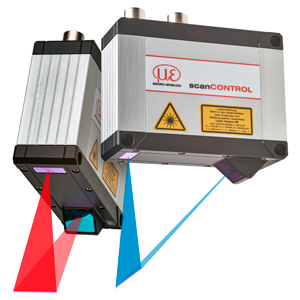

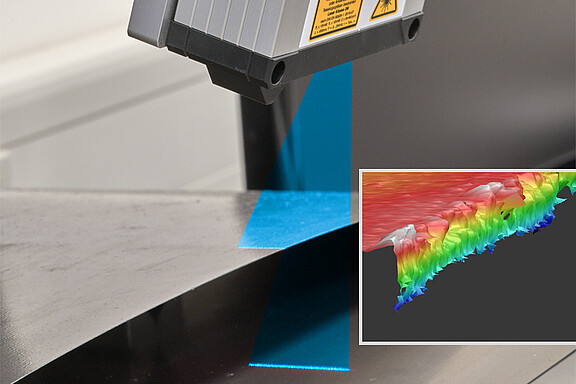

- レーザープロファイルスキャナ

- Configurator

- scanCONTROL 25x0

![scanCONTROL 25x0 レーザープロファイルスキャナ]() シリーズアプリケーション向けレーザースキャナ

シリーズアプリケーション向けレーザースキャナ - scanCONTROL 29x0

![scanCONTROL 29x0 レーザープロファイルスキャナ]() 高精度でコンパクトなレーザースキャナ

高精度でコンパクトなレーザースキャナ - scanCONTROL 30x2

![scanCONTROL 30x2 レーザープロファイルスキャナ]() パワフルな2D/3Dレーザースキャナ

パワフルな2D/3Dレーザースキャナ - scanCONTROL 30x0

![scanCONTROL 30x0 レーザープロファイルスキャナ]() 高性能レーザースキャナ

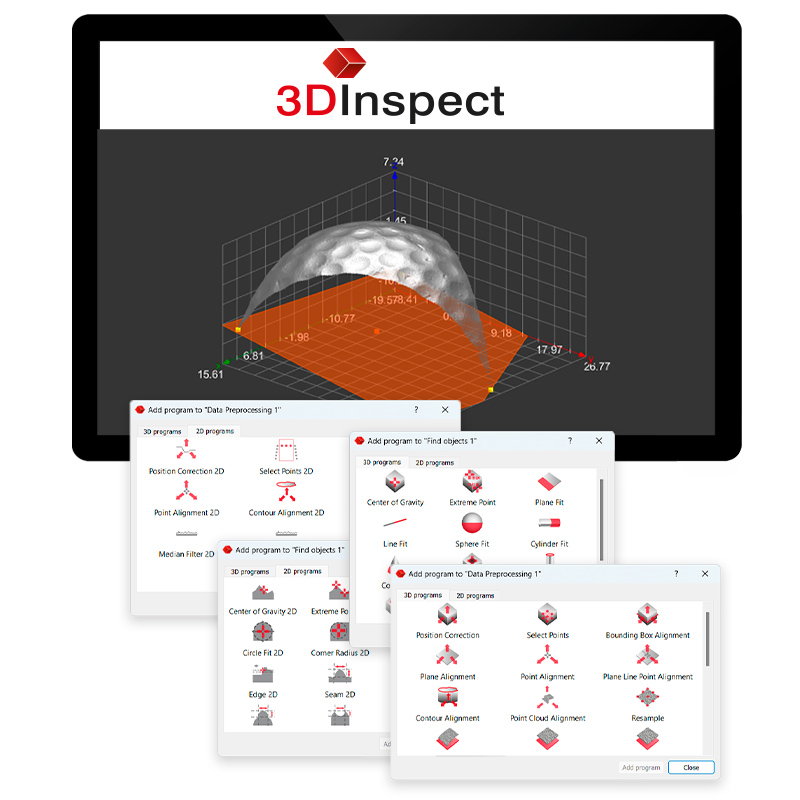

高性能レーザースキャナ - ソフトウェア

- オプション & 付属品

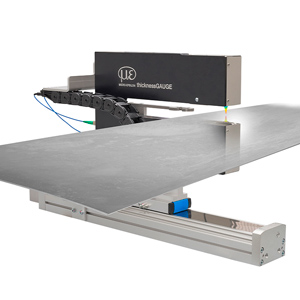

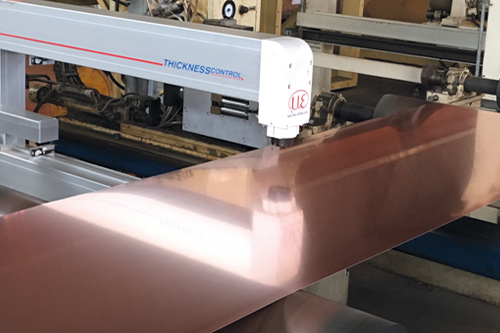

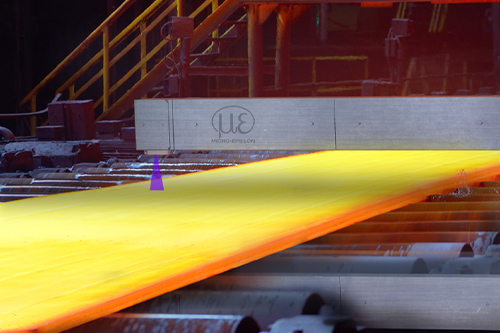

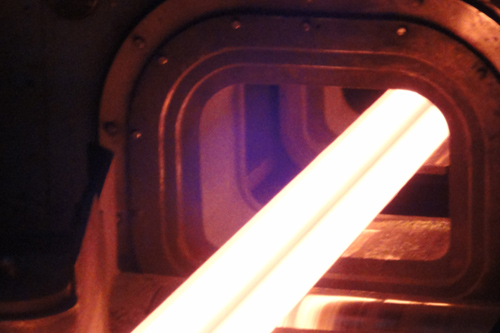

- 測定システム

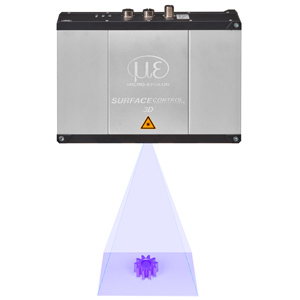

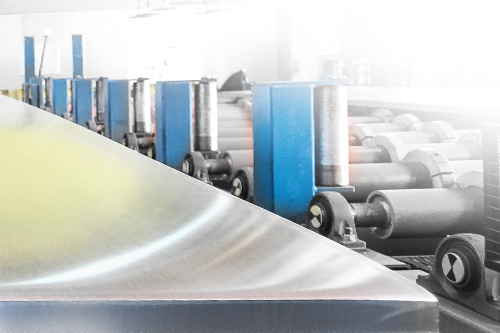

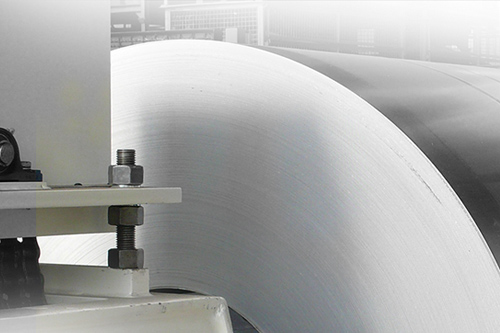

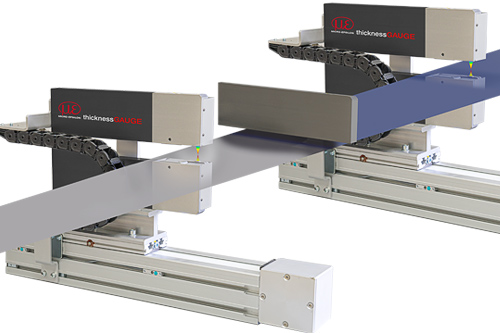

- 精密な厚さ測定のためのセンサシステム

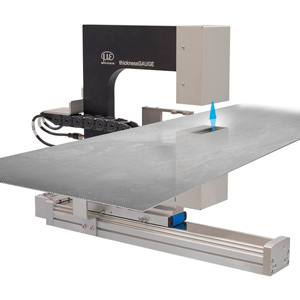

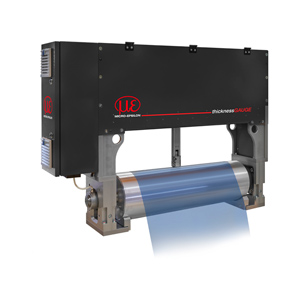

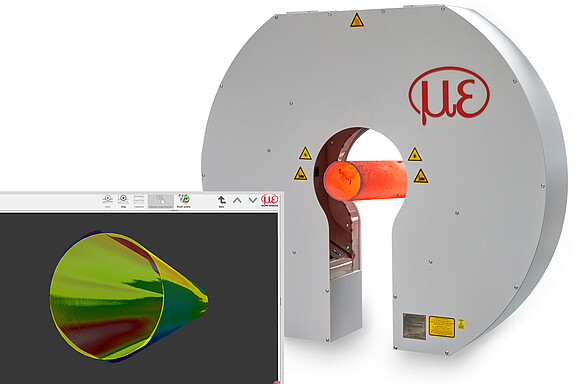

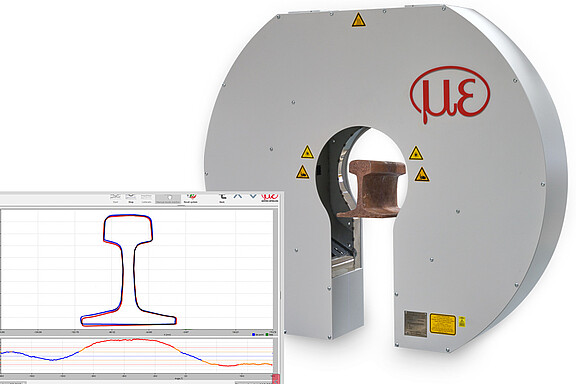

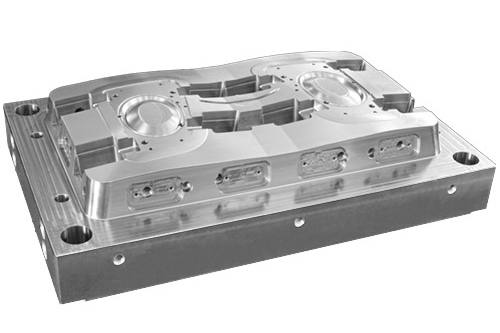

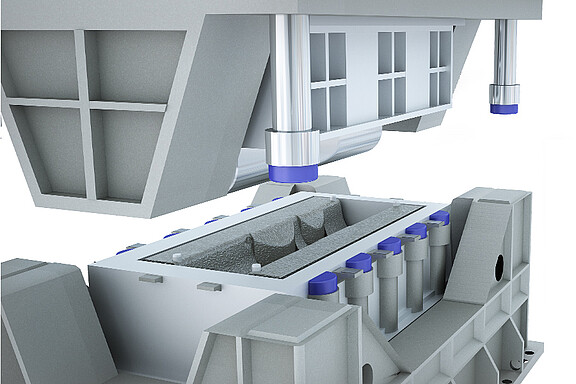

- thicknessGAUGE 3D

![thicknessGAUGE 3D 精密な厚さ測定のためのセンサシステム]() インライン厚さ・プロファイル測定

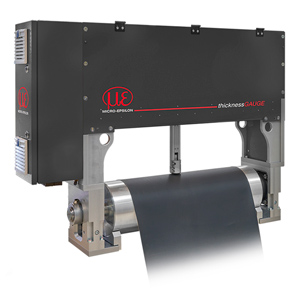

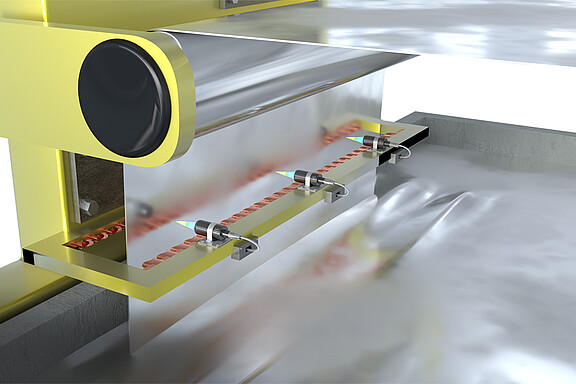

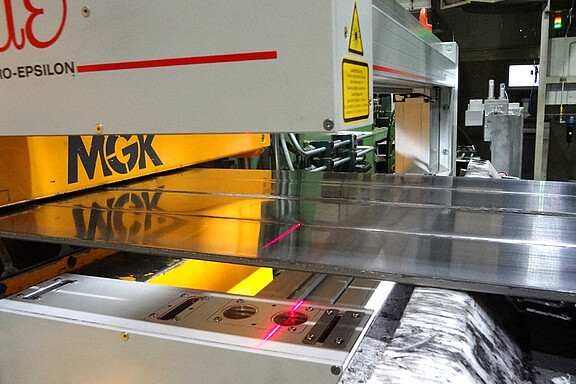

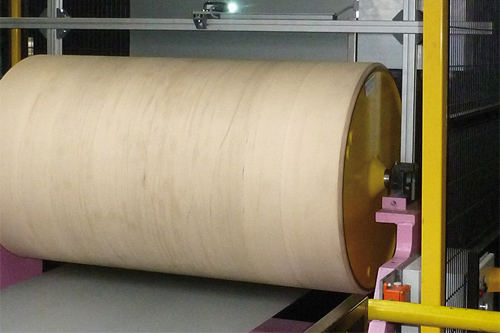

インライン厚さ・プロファイル測定 - thicknessGAUGE C.LL

![thicknessGAUGE C.LL 精密な厚さ測定のためのセンサシステム]() インライン厚さ測定(レーザーセンサ)

インライン厚さ測定(レーザーセンサ) - thicknessGAUGE C.C

![thicknessGAUGE C.C 精密な厚さ測定のためのセンサシステム]() インライン厚さ測定(共焦点)

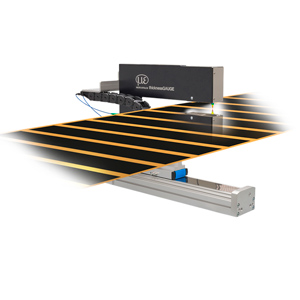

インライン厚さ測定(共焦点) - thicknessGAUGE C.LP

![thicknessGAUGE C.LP 精密な厚さ測定のためのセンサシステム]() インライン厚さ測定(レーザープロファイルセンサ)

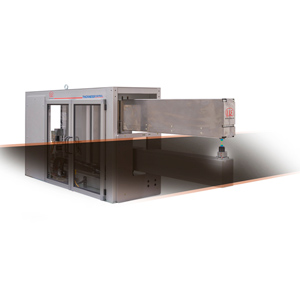

インライン厚さ測定(レーザープロファイルセンサ) - thicknessGAUGE O.EC

![thicknessGAUGE O.EC 精密な厚さ測定のためのセンサシステム]() インライン厚さ測定(渦電流/静電容量式)

インライン厚さ測定(渦電流/静電容量式)

- thicknessGAUGE 3D

- 電池生産用の検査システム

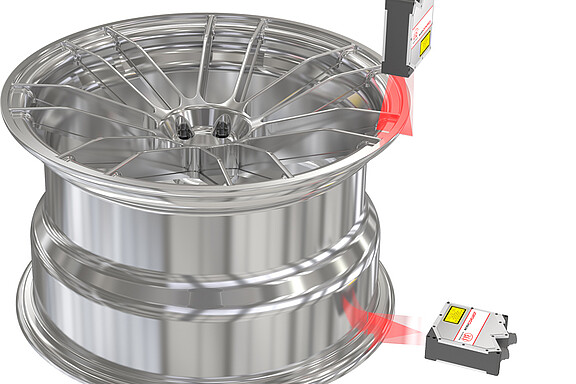

- Inspection and production systems for the tire industry

- 精密な厚さ測定のためのセンサシステム

- アプリケーション

- お問い合わせ