Business units

Measurement competence from a single source

Micro-Epsilon offers a world-leading range of precision sensors, measuring systems and customized solutions from a single source. Our high-precision sensors and measuring systems solve measurement tasks in all major industries - from machine building and automated production lines to integrated OEM solutions. They impress with their high accuracy, integrability and series production capability.

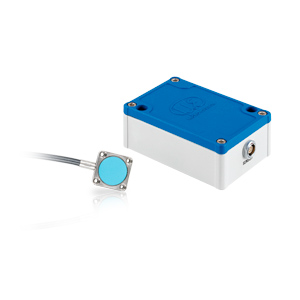

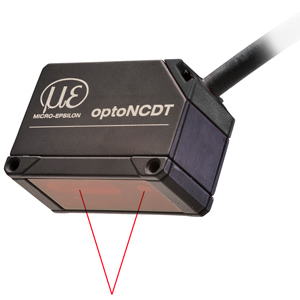

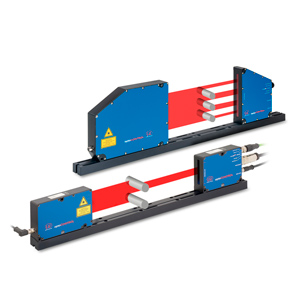

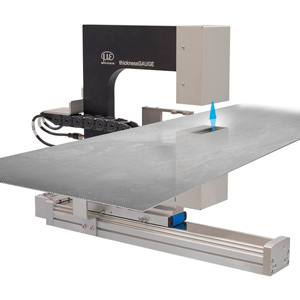

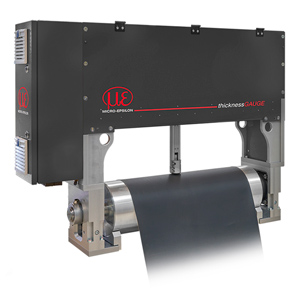

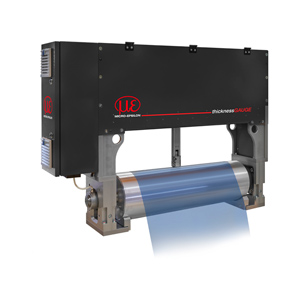

Industrial sensor technology

The »Industrial sensor technology« business unit covers a wide range of sensors and measuring systems designed for industrial series production. The sensors impress even in industrial environments with oil, dirt, pressure, vibration and fluctuating temperatures by robust design and high accuracy. Ease of integration, miniature design and intelligent signal processing using state-of-the-art interfaces are further features that distinguish the portfolio.

For series projects, we offer a large pool of measurement methods, the development know-how and the necessary production capacities to manufacture sensors in large quantities. These can be exactly adapted to the customer’s requirements in order to achieve maximum efficiency with regard to technical and economical specifications. In addition to metrological requirements, our development engineers also coordinate components and parts with our customers in order to ensure cost-effective production. In addition to the variety of technologies, application consulting plays an important role in implementing measurement tasks economically.

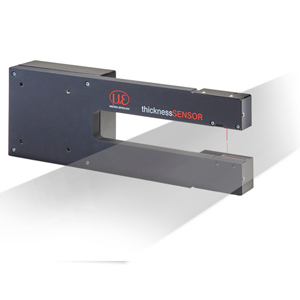

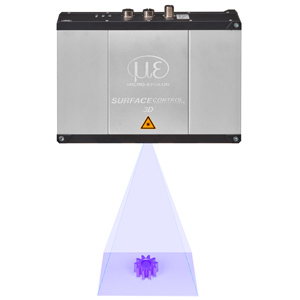

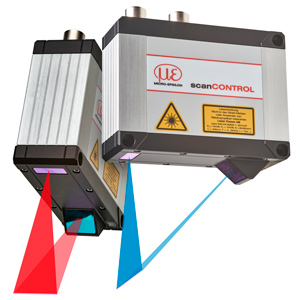

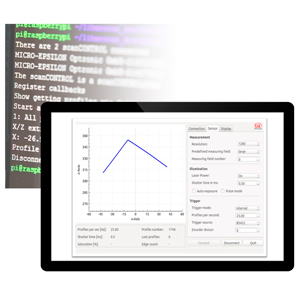

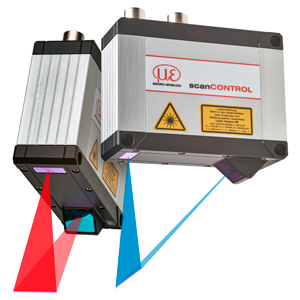

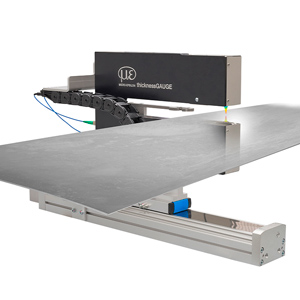

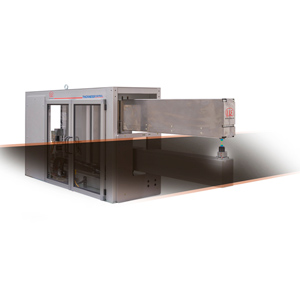

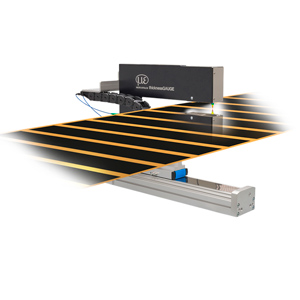

3D sensor technology

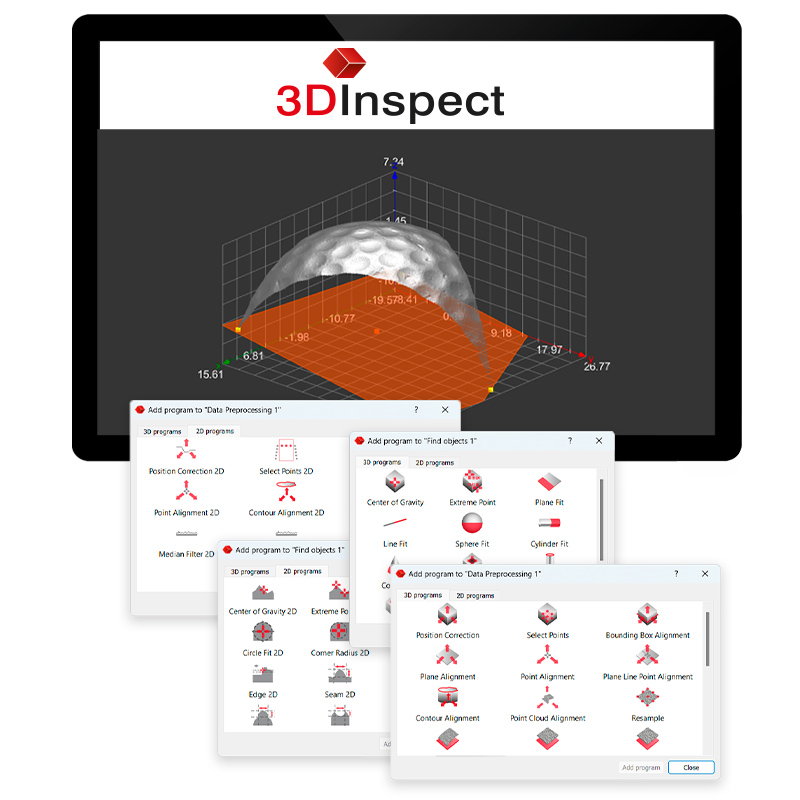

In automated surface inspection and geometry measurement, there is no way around precise 3D sensor technology. It offers numerous possibilities due to a fast and real 3D display from various perspectives. In the »3D sensor technology« business unit, we offer innovative 3D sensors for inline measuring and inspection tasks.

These 3D sensors impress with measurement accuracy in the sub-micron range. In combination with the innovative 3DInspect software and the GenICam / GigE Vision standards, the sensors can be integrated into modern environments. The 3D point clouds can be evaluated directly for process control.

3D sensors are used for geometric component shape inspection, position determination, presence checking, and flatness or planarity measurement in various applications. All sensors can be used in-line, stationary and on a robot. Fast inspection and evaluation enable short cycle times, allowing demanding inline measurement tasks to be solved reliably.

Micro-Epsilon at a glance

- High-tech measurement technology Made in Germany

- Consulting, development, production and implementation from a single source

- Worldwide industry and application support

- Solution expertise from catalog products to OEM series

- Technology know-how from more than 50 years of sensor development with over 400 active patents and patent applications

- Real added value and competitive advantages for your application